The pace of global supply chain expansion is to slow, with the next generation to be characterised by a shift in the nature of manufacturing centres.

A new report from Standard Chartered suggests that while the supply chain expansion which has “transformed trade and the world economy in the last 30 years” will continue, it will do so at a more subdued pace, and will be defined by new patterns, including devolution of technology to local manufacturing bases.

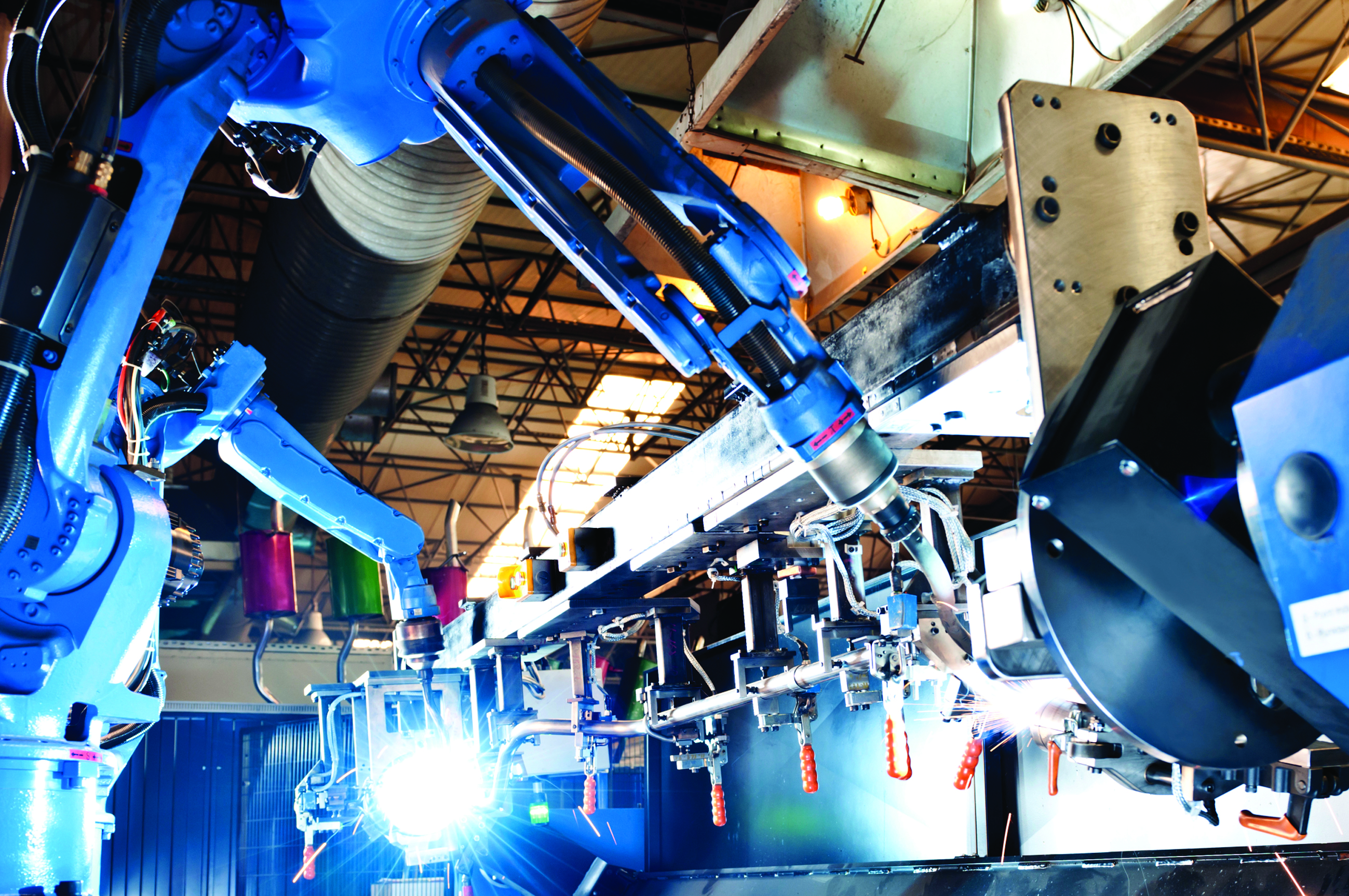

While there has been much talk in recent years of a continual and evolving shift in manufacturing to low-cost hubs (think the West to China, China to Southeast Asia), the report’s authors argue that technological advancements such as robotics, mobile and 3D printing could alleviate the need to pursue low-wage production.

And while the shift to Southeast Asia will continue, expect this to continue to evolve until eventually India and Africa become the manufacturing hubs of choice.

“Generally, the lower the wages, the poorer the infrastructure,” John Calverley, Standard Chartered

Standard Chartered’s head of thematic research John Calverley tells GTR that while Asean nations are certainly in vogue at the moment (indeed the Australian bank ANZ recently authored a report predicting it would become the “new manufacturing superpower”), the challenges it faces are myriad and could restrict its push to become the new factory of the world.

“Generally, the lower the wages, the poorer the infrastructure,” Calverley explains, but adds that initiatives such as the AIIB and China’s One Belt One Road plan could help plug some of these significant gaps.

He adds: “But Asean has cost advantages compared to China and also offers the chance for international companies to diversify away from reliance only on China. Still, we don’t see Asean actually replacing China. It is more that the centre of gravity for low-cost manufacturing will shift westwards, partly to inland China, and also to Asean and India. So, new investment will increasingly not go to coastal China so much.”

Much has been made of India’s potential as a trade and manufacturing superpower, particularly since Narendra Modi’s election, and the launch of his much-vaunted “Made in India” campaign, designed at attracting investment in the country’s production centres.

The report believes that the steps the government has taken to boost transparency, encourage FDI and lowering bureaucracy are positive, as is the investment in vital trade infrastructure. However many challenges remain.

“Building a well-functioning, accountable bureaucracy that is capable of making quick decisions is a prerequisite for better implementation of government policies,” Calverley says, praising the streamlining process which, among other things, cut decision-making processes and setting two-week deadlines to answer queries. However, the lack of labour market deregulation and land law reform has yet to be seriously addressed.

While some parts of East Asia are often viewed as the home of high-tech innovation, in terms of its usage in trade circles, the picture is very mixed. “The likes of Singapore, Korea, China, Japan and even Thailand are doing better at technology creation than their per capita income levels would suggest while countries such as India, Pakistan and Bangladesh are largely lagging the developed world in terms of innovation,” he says.

However the significant investment in robotics in the likes of China and Japan could see it rival western superpowers to become the production innovators of the future.